FlexMove Wedge Conveyors

Benefits of FlexMove Wedge Elevator:

Our Wedge Conveyors are used to take products from production floor level to a higher level or vice versa. Products are wedged between opposing conveyors

aligned vertically or horizontally and are moved swiftly but securely.

Wedge Conveyors are easy to construct, lightweight and have compact footprints. Its rapid transfer rate makes it ideal for use in continuous, high capacity operations such as packaging lines. Built with aluminum or stainless steel, it meets the stringent hygiene standard

required for medical and cosmetic packaging.

They can be configured differently for a variety of uses, such as a transition between different levels, depucking operations, inverted rinse operations, and even

for creating a passage way on the production floor.

How a wedge conveyor works:

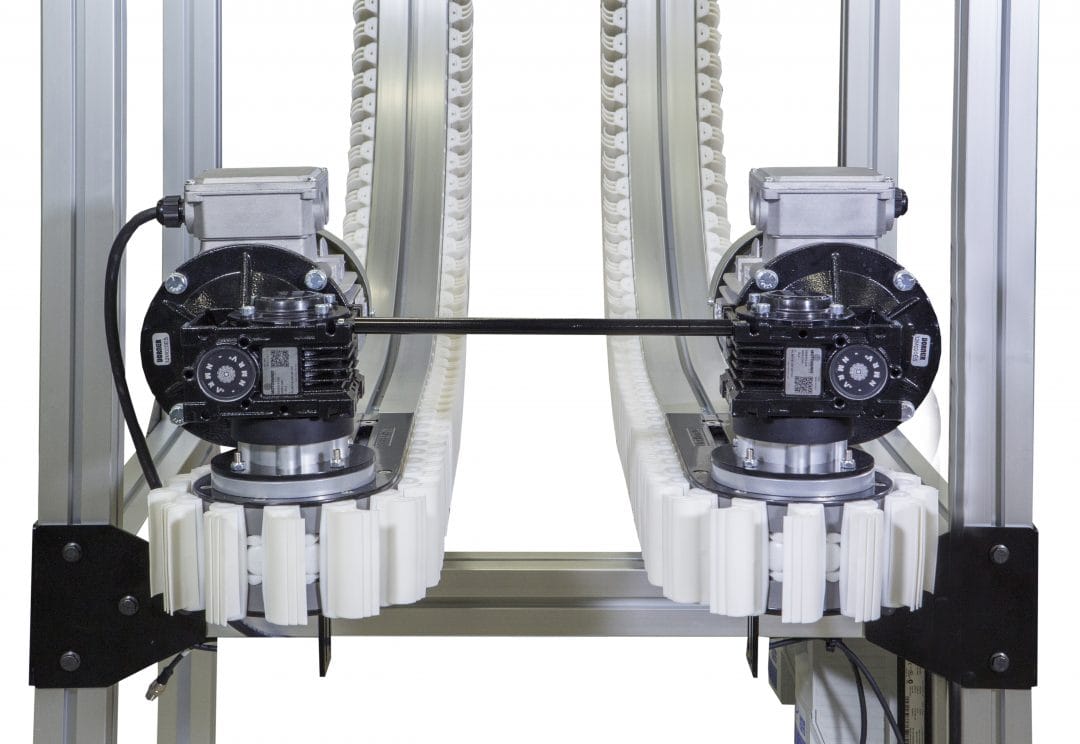

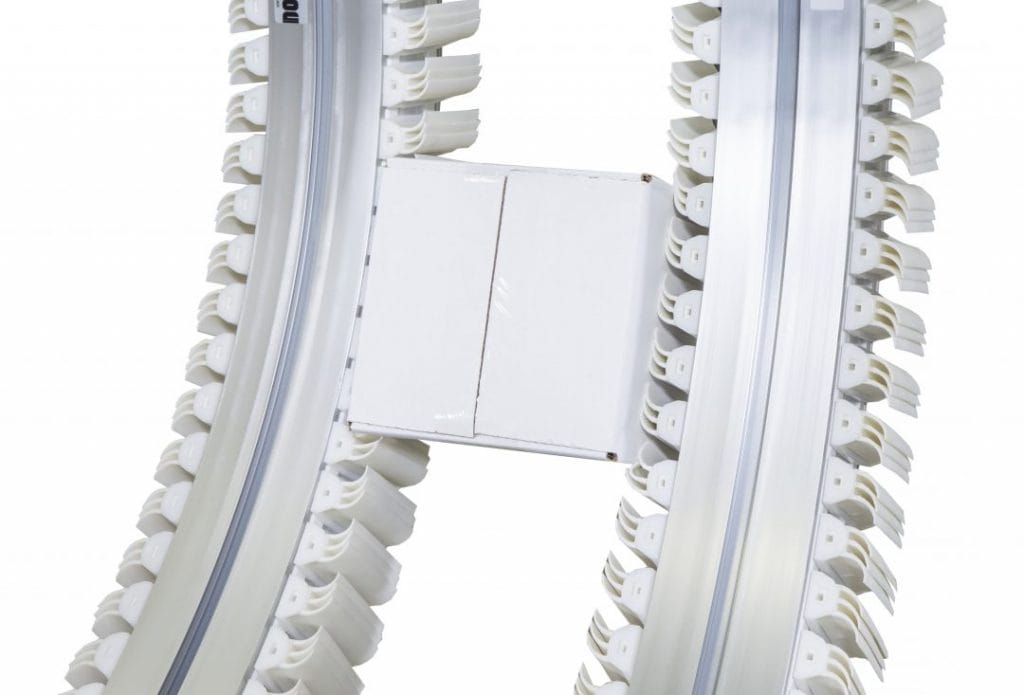

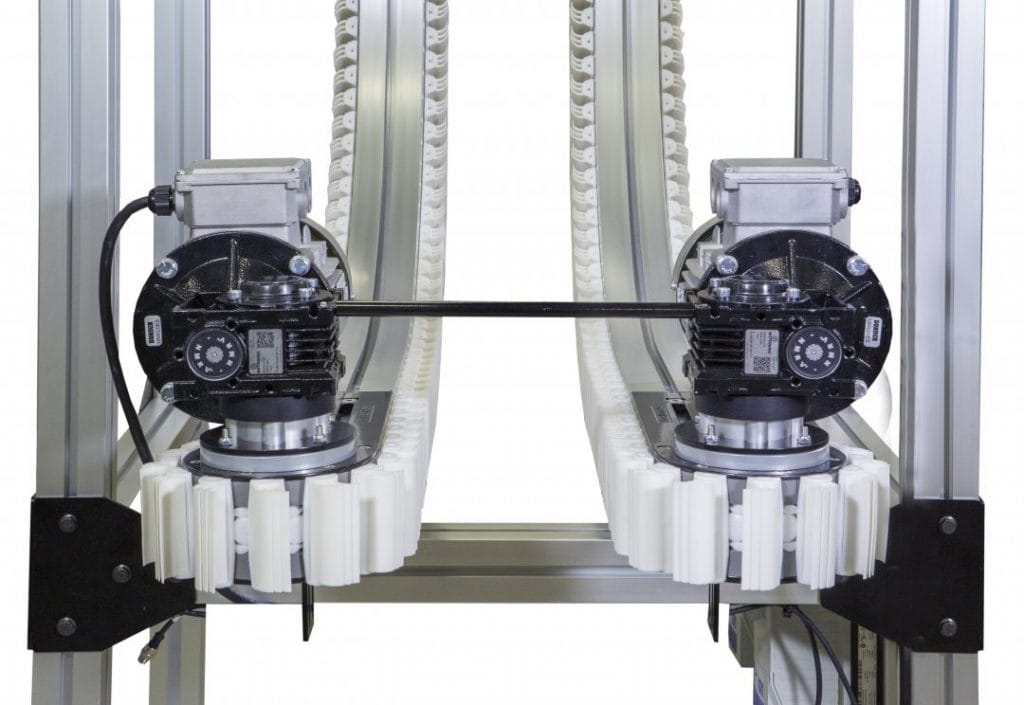

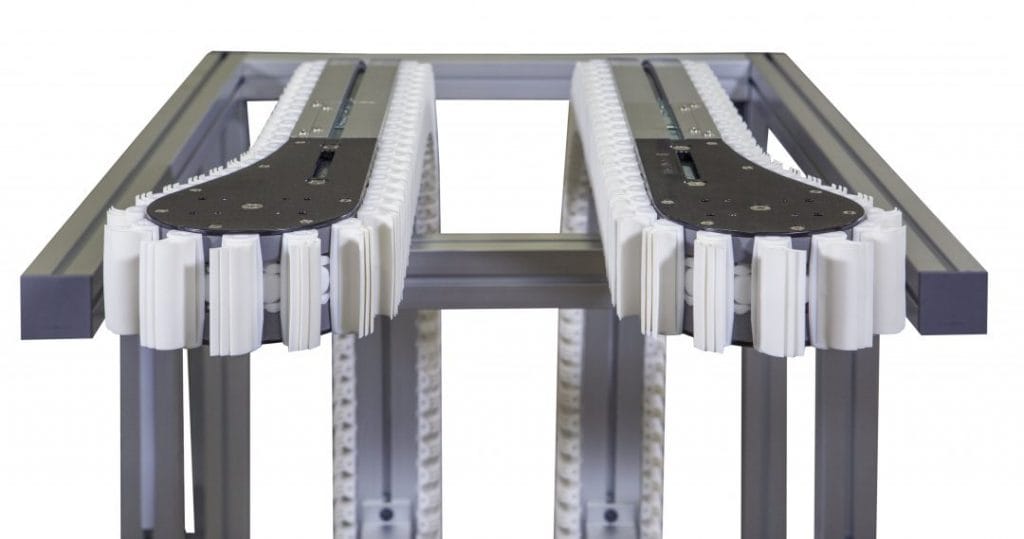

- Constructed with two parallel FlexMove conveyors utilizing a urethane gripper chain that wedge the sides of the product to lift or lower it vertically.

- Products are fed into the Wedge Conveyor from a horizontal conveyor with at least a product length gap to avoid hitting each other while going through the vertical transition. Products then exit onto a horizontal conveyor.

- Can be used with products of various sizes and shapes including boxes, totes, cans, plastic containers and bottles. Product must be able to withstand some side pressure.

- Vertical transfer can be through a wheel corner or plain bend corner. Wheel corner is generally limited to product

less than 100mm in length. - Can be configured with a manual adjustable conveyor positioner for quick product size changeover. Various configurations can also change product orientation.

View the complete Specification Sheet here: FlexMove Wedge Conveyor Spec Sheet

General Specifications

- 45 mm, 65 mm and 85 mm belt widths

- Minimum lower height: 457 mm (18 in)

- Maximum upper height: 6096 mm (240 in)

- Maximum individual product weight: 4.6 kg (10 lbs)

- Maximum total weight: 90 kg(200 lbs)

- Speeds: Up to 52.2 m/min (171 ft/min)

- Slight variation in product size is compensated for by the flexible wedge fingers without having to adjust the conveyor

Available Configurations

- S Type: The product is elevated or lowered along a straight path. Most common Configuration

- C Type: The product is elevated or lowered while changing the orientation or flipping the product.

- N (U) Type: The product is elevated and lowered (opposite for U shape) to allow for clearance below the conveyor.

- O Type: The product follows the loop, tipped upside down and conveyed back to near the infeed.

Accessories

Support Stands

Gearmotors

Profiles & Guiding

Manuals & Literature

Looking for Service Manuals? Search for Service Manuals by part number or product type HERE.

| Engineering Manuals | Pages | File Size |

| FlexMove Engineering Manual | 244 | 55.2 MB |

| Literature | Pages | File Size |

| Wedge Brochure | 2 | 2.4 MB |

| FlexMove Brochure | 6 | 2.9 MB |

| FlexMove Wedge Conveyor Spec Sheet | 10 | 2 MB |